Induction Heating Services

Welcome to Fluxtrol’s induction heating production services. Our Fluxtrol team provides two clear production workflows for our customers:

- Pre-Production Induction Applications - for customers that want to build a new induction heating coil(s) or induction application(s).

- Existing Production Induction Applications - for customers that want to improve on an existing induction heating coil(s) or induction application(s).

These workflows help our customers engineer induction heating coils, select and properly install the correct Fluxtrol SMC materials, and successfully launch the application/process into new or exciting production environments.

Pre-Production Induction Applications

The Fluxtrol Team uses the following process to build all-new induction applications:

- Define a full application description to meet performance and functionality targets.

- Deploy Computer Simulation

- Engineer the Induction Heating Coil

- Manufacture the Induction Heating Coil

- Simulation and Testing Comparison - Run the experiment/development

- a. Compare experimental results to simulation results

Existing Production Induction Applications

The Fluxtrol Team uses the following process to improve existing induction applications:

- Use simulation to describe/understand existing application

- Run the experiment/acquire data

- Break down the application and draw the coil

- Deploy Computer Simulation to explain results

- Compare

- Computer Simulation to results

- (Not applicable here) Propose new coil design/parameters

- Test the new process

Detailed Pre-Production Workflow

The Workflow

1. Application Description/Goal Computer Simulation

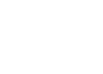

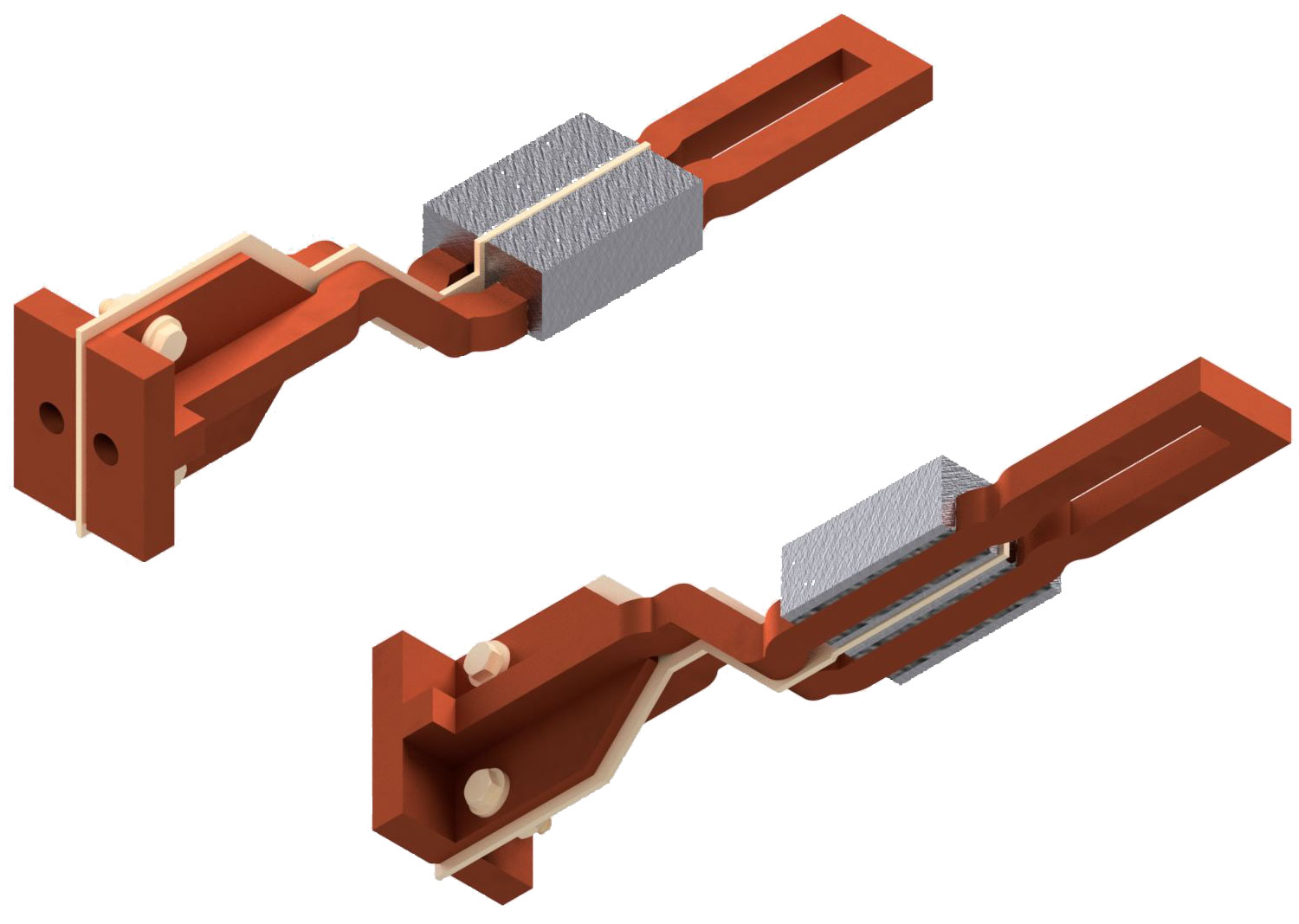

Hairpin coil designs are a type of coils that are commonly used in the induction heating industry. These coils are used for heating flat and non-flat surfaces. The use of magnetic controllers, especially soft magnetic composites (SMC’s) is common with hairpin coils for increasing efficiency and heat control.

The goal of this project is to compare heating performance of a hairpin coil with and without the use of SMC’s. For easier comparison, Fluxtrol A SMC is applied to a half of a coil, while the other half has no controller. Additionally, the coil is attached to a robotic for scanning, which is common practice with induction heating coils.

Computer simulation will be used to analyze and predict the heating of a stainless-steel sheet. A coil will be designed and manufactured based on the simulation results for testing.

2. Computer Simulation

A. 2D Simulation

2D, plane parallel, static simulations using Flux 2D FEM software are made for both cross-sections. The use of 2D simulation is a simplification of the geometry and is sufficient in many cases.

The 2D simulation results show a significant increase in temperature and efficiency for the hairpin coil with the Fluxtrol A SMC, this is due to two factors:

- The use of SMC’s concentrates the magnetic field, and heating, below the coil

- The use of SMC’s redirects the majority of the current from the internal faces to the bottom heat face.

B. 3D Simulation - Full Comparison

3D, full geometry, scanning simulations using Flux 3D FEM software are made. 3D simulation accounts for the full geometry but requires longer setup and solve times.

The 3D simulation results, as with the 2D simulation results, showed a significant increase in the temperature and efficiency in the section with the Fluxtrol A SMC.

Simulation is used to predict electrical parameters, such as voltage, current, power, and inductance. The predicted electrical parameters are used to choose the proper power supply and its tuning parameters.

3. Engineer the Induction Heating Coil

After the simulation is completed, the coil engineering stage comes next. In the coil engineering stage, the coil is fully drawn 3D for manufacturing.

In the engineering stage, all coil details are completed, such as the coil head, SMC design, water cooling path, mechanical components, insulations, and others.

4. Induction Heating Coil Manufacturing

Coils can be manufactured from copper tubing, machined copper, or both. In the case of this hairpin coil, ½’’ rectangular copper tubing is used with Fluxtrol A SMC on one of the sections, colored in green. Rectangular tubing is more advantageous for SMC placement and adhesion, in addition to a flat heating face.

The MACHINING of Fluxtrol A SMC is similar to light metals. The use of High-Speed Steel, Tungsten Carbide, TiN coated or AlTiN coated tools. It is also recommended to climb cut into the stock material, exiting the detail, and entering on opposite end of cut, to meet in the middle.

APPLYING the Fluxtrol A SMC to this hairpin coil was accomplished using JB Weld epoxy. The Fluxtrol A SMC is coated with a green Cerakote coating, adding PROTECTION to the Fluxtrol A SMC against corrosion.

Like many other coils, MAINTENANCE of this hairpin coil is as simple as cleaning debris with a nylon bristle brush. Placing an insulating material between in the middle of the concentrator material prevents a short circuit. Visual control of the concentrator and coil is key to identifying excess buildups of process residue on the coil that can potentially lead to arching.

5. Simulation and Testing Comparison