Induction Heat Treating and Melting

Heat treating of different details is a traditional area of Research at CIT. It includes analysis of coupled electromagnetic and thermal phenomena during induction heating of steels and other materials, methods of computer simulation, material properties required for simulation and development of new processes and their tests in laboratory. In recent years, we conducted a study of stress and Deformation evolution in processes of induction hardening of different parts in close cooperation with Dante Solutions. This study ranged from initial analysis of coupled electromagnetic, thermal, structural and mechanical phenomena in bodies of simple geometry to simulation of stress and deformation dynamics in the axle shafts throughout the whole process of manufacturing and service performance. Dana Corporation also participated in this study, the results of which were presented in several publications.

No content found

Heat Treating and Melting Properties

Heat Treating and Melting Graphs

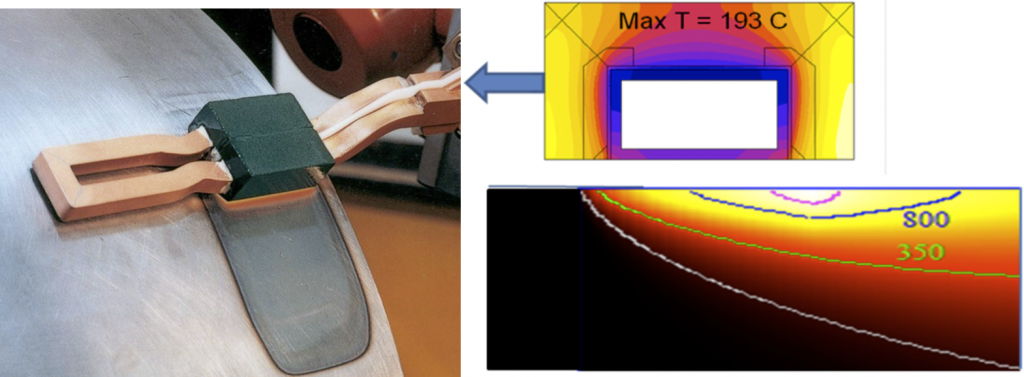

Study of stresses and deformations during scan hardening of a thick tube ID surface

Main attention in melting was paid to high-tech technologies such as cold crucible melting and refining of Silicon, atomization of Titanium alloys, production of Zirconium rods, etc. We demonstrated and proved in practice that optimal design of the melting system with special attention to magnetic flux control can lead to significant improvement in the process efficiency and product quality.

Multiple studies have been performed since this demonstration at the ASM show in 1999 and a firm knowledge base has been created for optimal design of induction systems using magnetic controllers.

It includes characterization of soft magnetic composites, study of the influence of magnetic controllers in different induction systems, application methods and performance prediction using computer simulation.

3D simulation of cold crucible, laboratory mockup and “crown” of residual metal after pouring Titanium alloy for atomization

Contact us today to learn more about our induction heat treating and melting research and development.