Magnetic Controller Protection

In many applications Fluxtrol controllers work in special conditions. Factors that can thwart use of controllers and the coil copper or cause their premature failure:

- Mechanical damage by the part or during the coil installation.

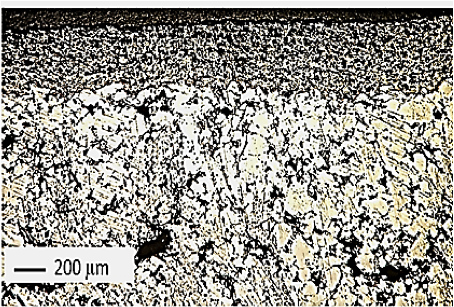

- Material overheating resulting in crumbling. Overheating may be caused by insufficient cooling of the coil, improper design and manufacturing or by concentrator separation from the coil tubing due to cracks in glue.

- Environmental impact. In vacuum furnaces special attention must be paid to controller cooling because of absence of convection. Aggressive atmospheres can cause chemical degradation of the controller.

- Electrical discharge from one living part to another or to ground can cause arcing and material “burning”.

- Many means and methods may be used for protection.

Contents

Mechanical damage is one of the main factors in coil / concentrator failure and proper preventive measures must be taken:

- Use coil design that prevents mechanical damage

- Check correct position of the concentrator relative to the coil, fixture and moving parts of machine

- Check conditions of carbide shoes or other components that provide required gap.

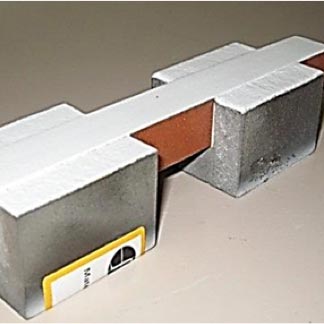

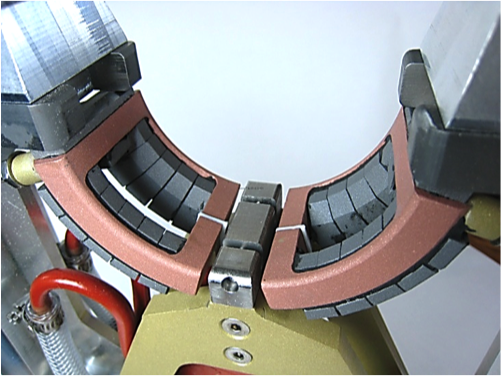

Induction heating coil with Fluxtrol for hardening of the crankshaft end main. Tungsten carbide separators provide required gap between the coil turns, Fluxtrol controllers and the shaft.

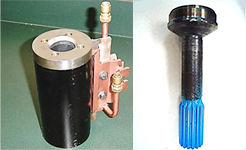

Multi-turn coil was used for low temperature heating of the shaft end before plastic coating. Mechanical impacts periodically caused the coil failure.

The coil turns were potted in epoxy and stainless steel guide installed on the coil entrance.

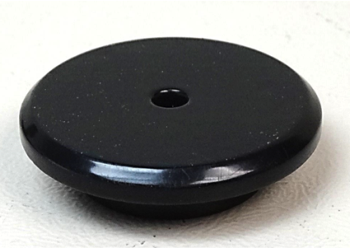

Fluxtrol ring was installed between the coil and the guide to prevent its heating.