Magnetic Flux Controllers in Induction Heating

Hysteresis is the lagging of the magnetization of a ferromagnetic material, such as iron, behind variations of the magnetizing field. When ferromagnetic materials are placed within a coil of wire carrying an electric current, the magnetizing field, or magnetic field strength H, caused by the current forces some or all of the atomic magnets in the material to align with the field. The net effect of this alignment is to increase the total magnetic field, or magnetic flux density B. The aligning process does not occur simultaneously or in step with the magnetizing field but lags behind it. (Britannica)

Hysteresis heating occurs only in magnetic materials. Hysteresis heating is caused by the internal “friction” of magnetic micro volumes (domains), which rotate following the orientation of the external magnetic field.

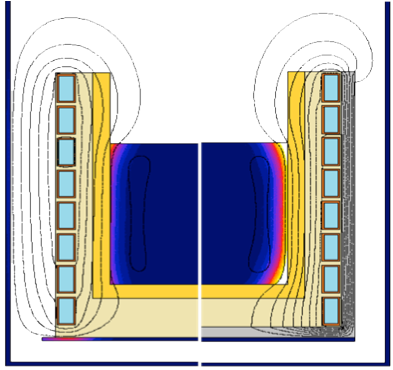

In solid materials, hysteresis losses are much lower than eddy current losses and often neglected in calculations. In particulate materials, they are a major or even only source of heating. In both cases, heat intensity is approximately proportional to magnetic flux value Φ squared. According to the laws of physics, magnetic flux flows along the closed path around the coil turns. Magnetic materials provide an easier way for magnetic flux to flow than air. By placing magnetic controllers in specific areas we can control the value and distribution of the magnetic flux density B. Depending upon its function (effects), a controller may be called a concentrator, diverter, shield, core, or impeder (in welding).

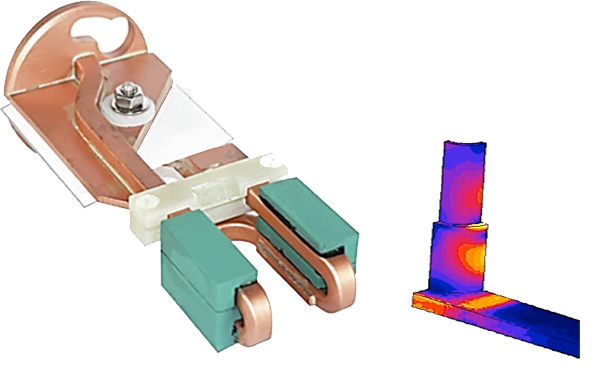

On many occasions, the controller can play several roles, such as concentrating field in one area and reducing in another. Due to a favorable combination of magnetic, thermal, electrical, and mechanical properties, Fluxtrol composites are excellent materials for different types of magnetic controllers.

Application of C-shaped concentrators surges magnetic flux produced by the coil current and increases power generated in the part. In addition, the concentrator makes power distribution under the coil “face” narrower and closer to a rectangular shape. This results in better utilization of induced power.

Power distribution along the part surface, magnetic field lines concentration and power density color maps for a coil with and without concentrator.