Authors: Rob Goldstein and Sean Muyskens

Overview:

- Induction tube welding industry

- Opportunity to improve efficiency

- Impeder benefits and material selection

- Conclusions

Induction Tube Welding Industry

- Induction tube welding is a key technology for the fabrication of tube and pipe

- Tube welding lines installations number over 1000 globally

- There exists an opportunity to improve the energy efficiency of these lines and greatly reduce the ecological cost of producing the same amount of product

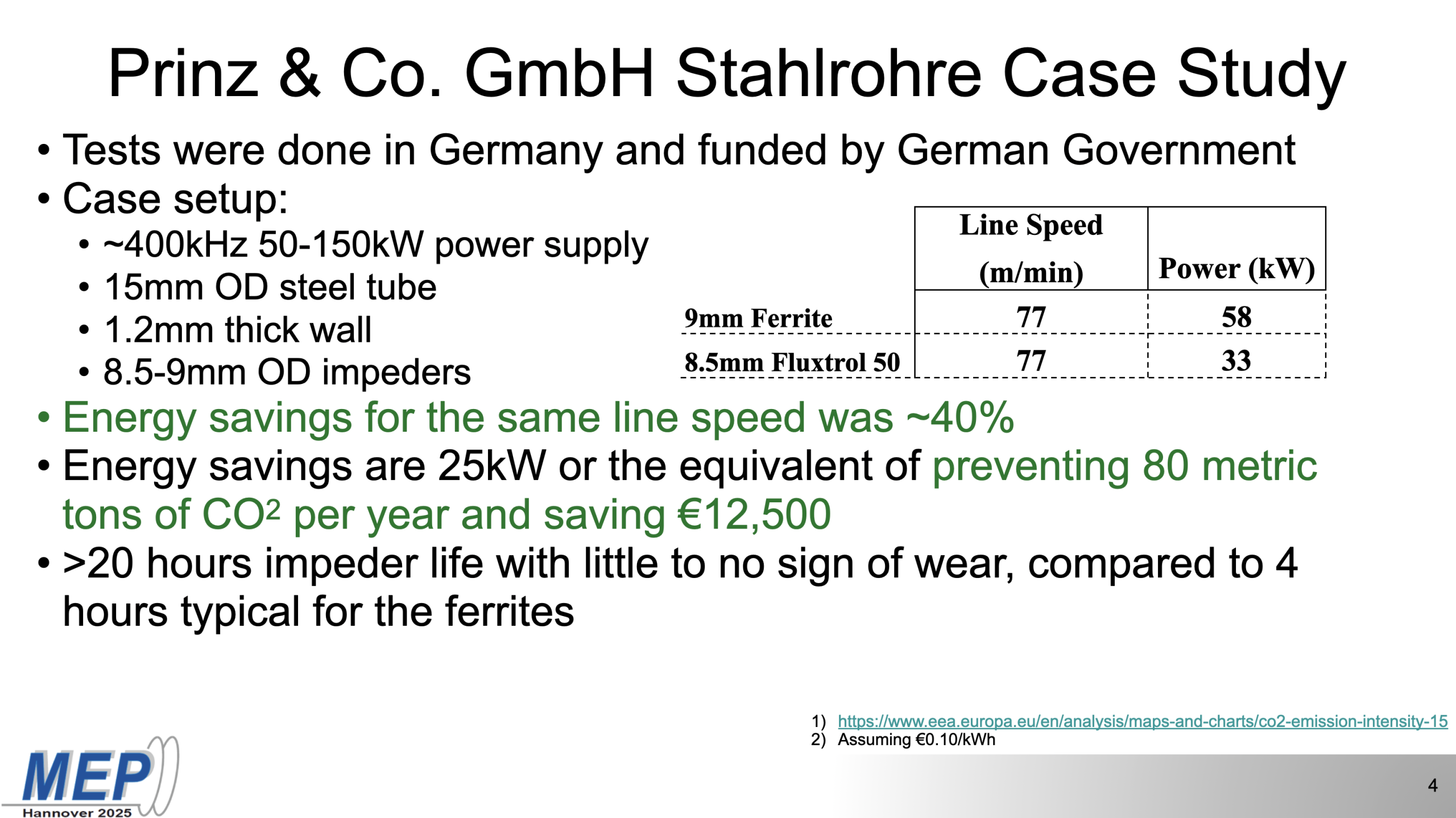

Prinz & Co. GmbH Stahlrohre Case Study

- Tests were done in Germany and funded by German Government

- Case setup:

- ~400kHz 50-150kW power supply

- 15mm OD steel tube

- 1.2mm thick wall

- 8.5-9mm OD impeders

- Energy savings for the same line speed was ~40%

- Energy savings are 25kW or the equivalent of preventing 80 metric tons of CO2 per year and saving €12,500

- >20 hours impeder life with little to no sign of wear, compared to 4 hours typical for the ferrites

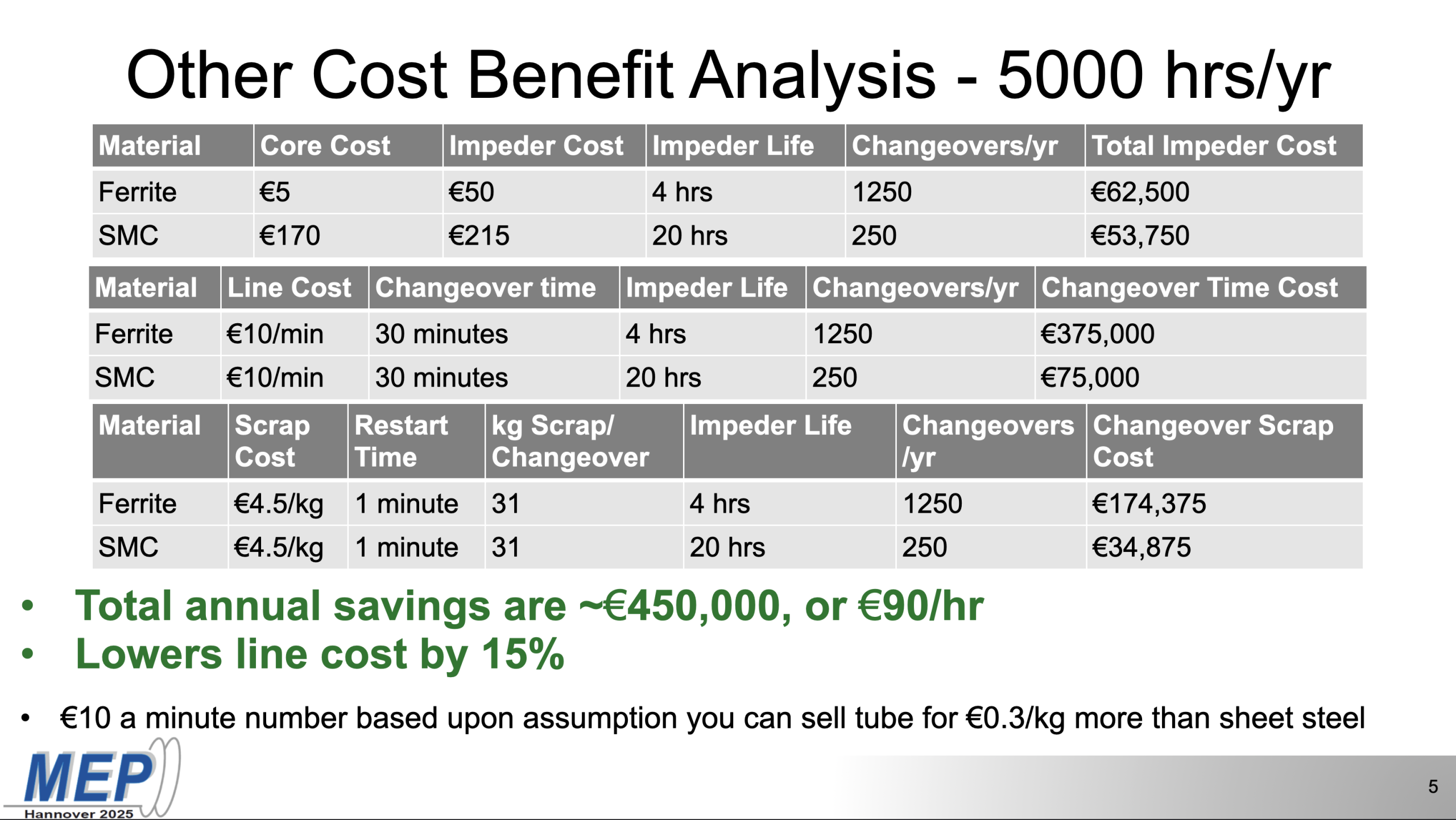

Other Cost Benefit Analysis - 5000 hrs/yr

- Total annual savings are ~€450,000, or €90/hr

- Lowers line cost by 15%

- €10 a minute number based upon assumption you can sell tube for €0.3/kg more than sheet steel

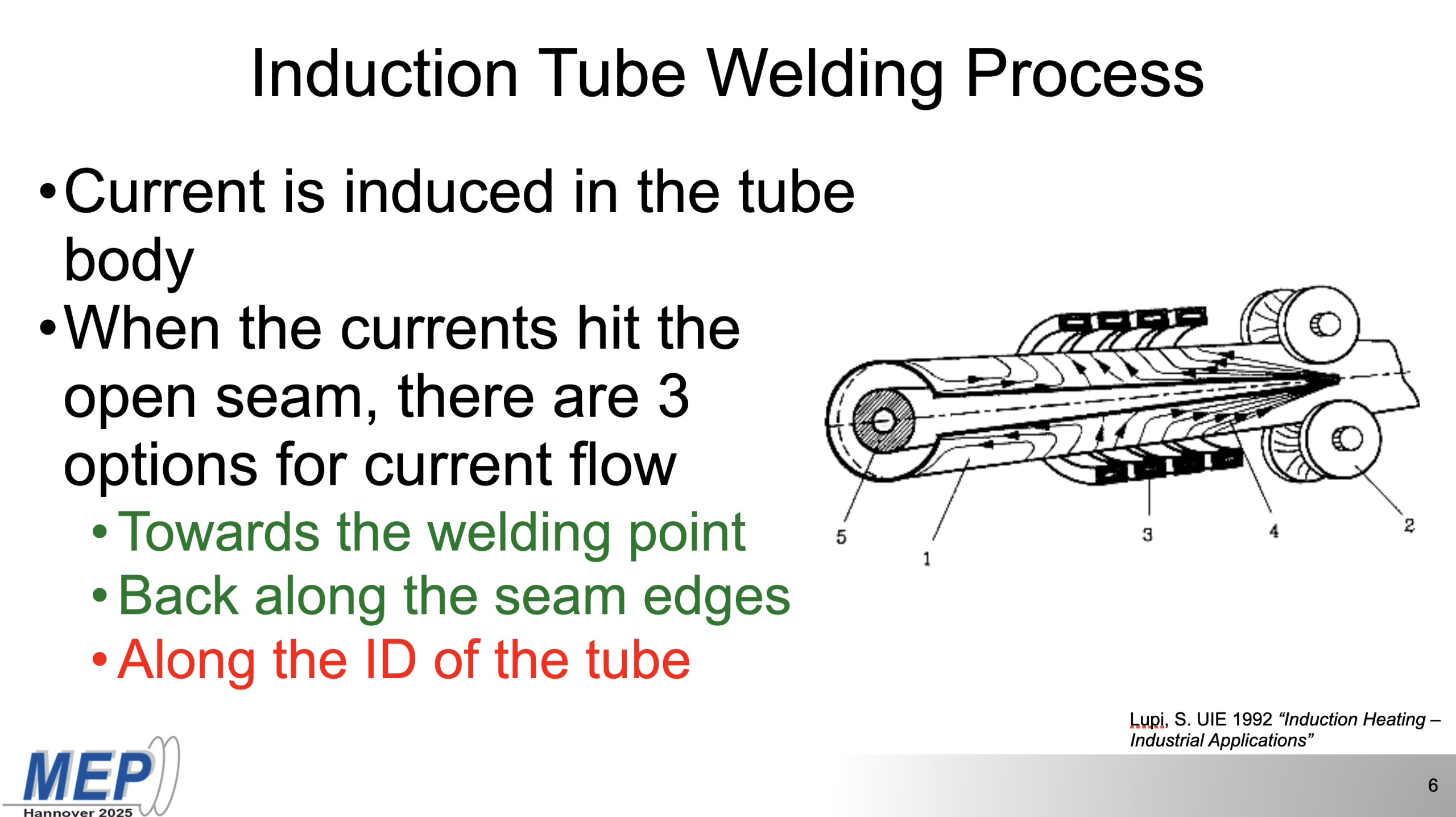

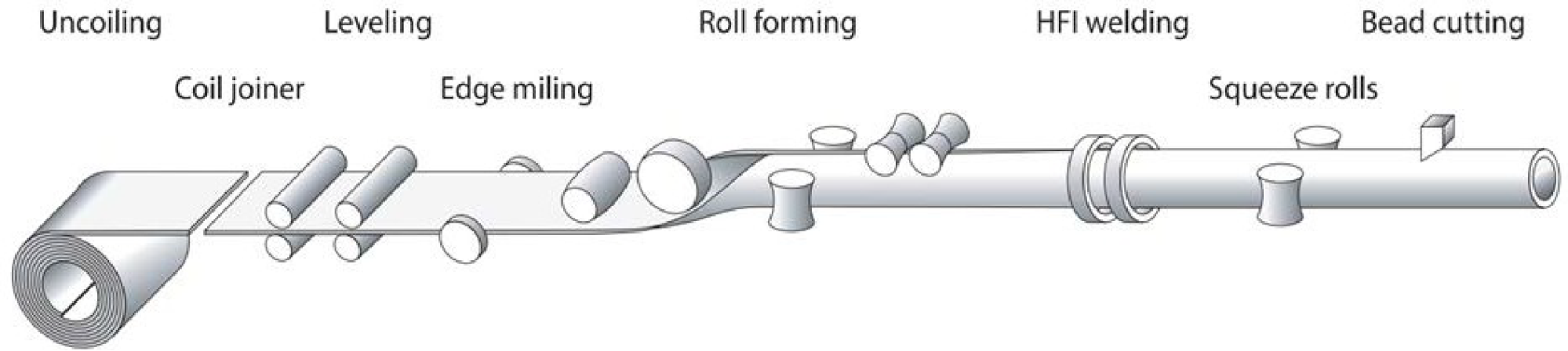

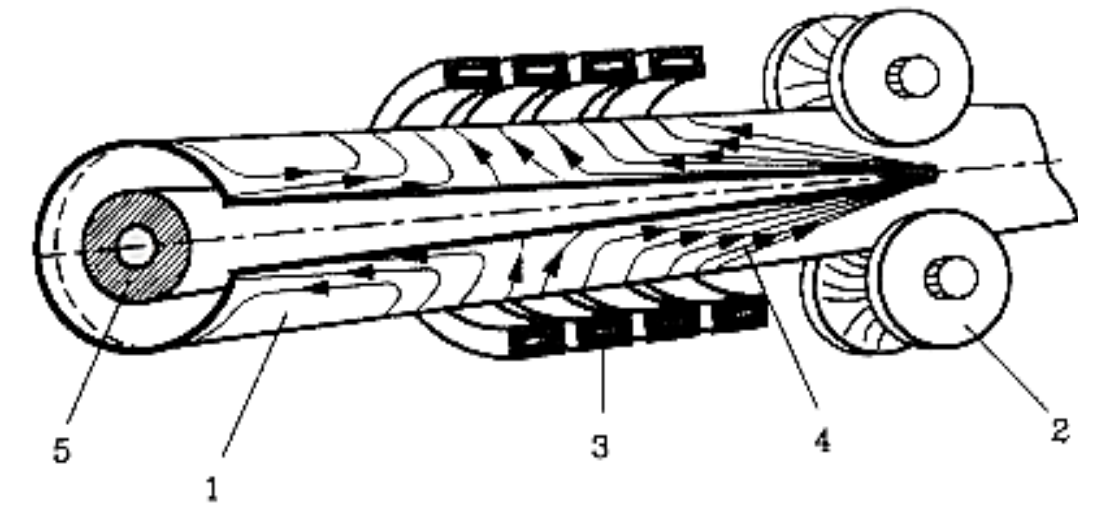

Induction Tube Welding Process

- Current is induced in the tube body

- When the currents hit the open seam, there are 3 options for current flow

- Towards the welding point

- Back along the seam edges

- Along the ID of the tube

Inductive Tube Welding Market Trends

- The availability of higher, more efficient power at choice of frequencies

- Improved material handling

- More Advanced Process Monitoring and Control – Industry 4.0

- Improved Material Cutting

- Limiting factor in the performance of many small tube installations is now the impeder

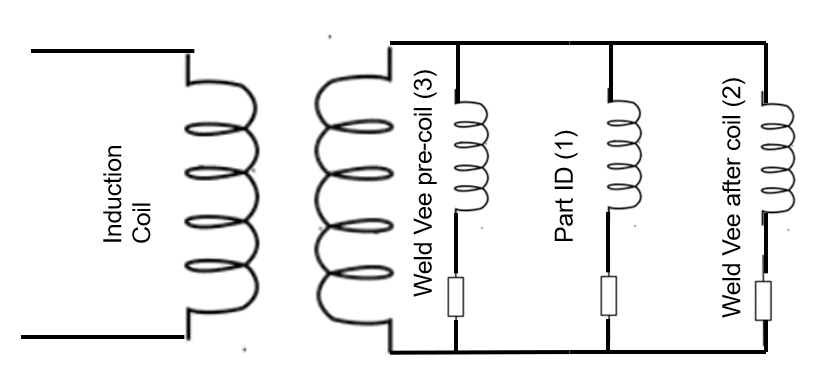

What is an impeder?

- An assembly that contains a soft magnetic material that “impedes” the current flow on the inside of the pipe

- Typically manufactured using ferrite materials

- Fixtured within the forming tube

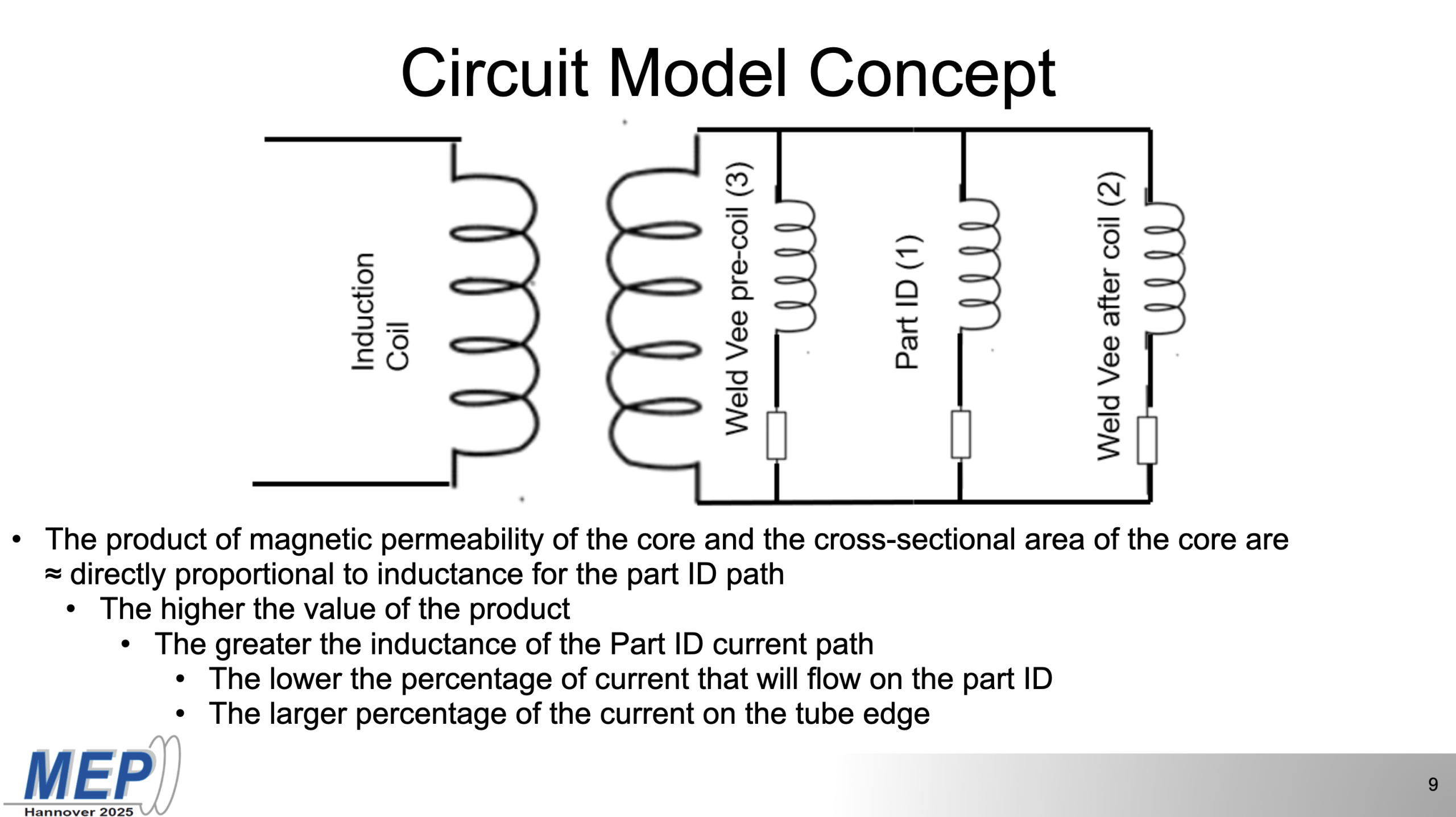

- The product of magnetic permeability of the core and the cross-sectional area of the core are ≈ directly proportional to inductance for the part ID path

- The higher the value of the product

- The greater the inductance of the Part ID current path

- The lower the percentage of current that will flow on the part ID

- The larger percentage of the current on the tube edge

- The greater the inductance of the Part ID current path

- The higher the value of the product

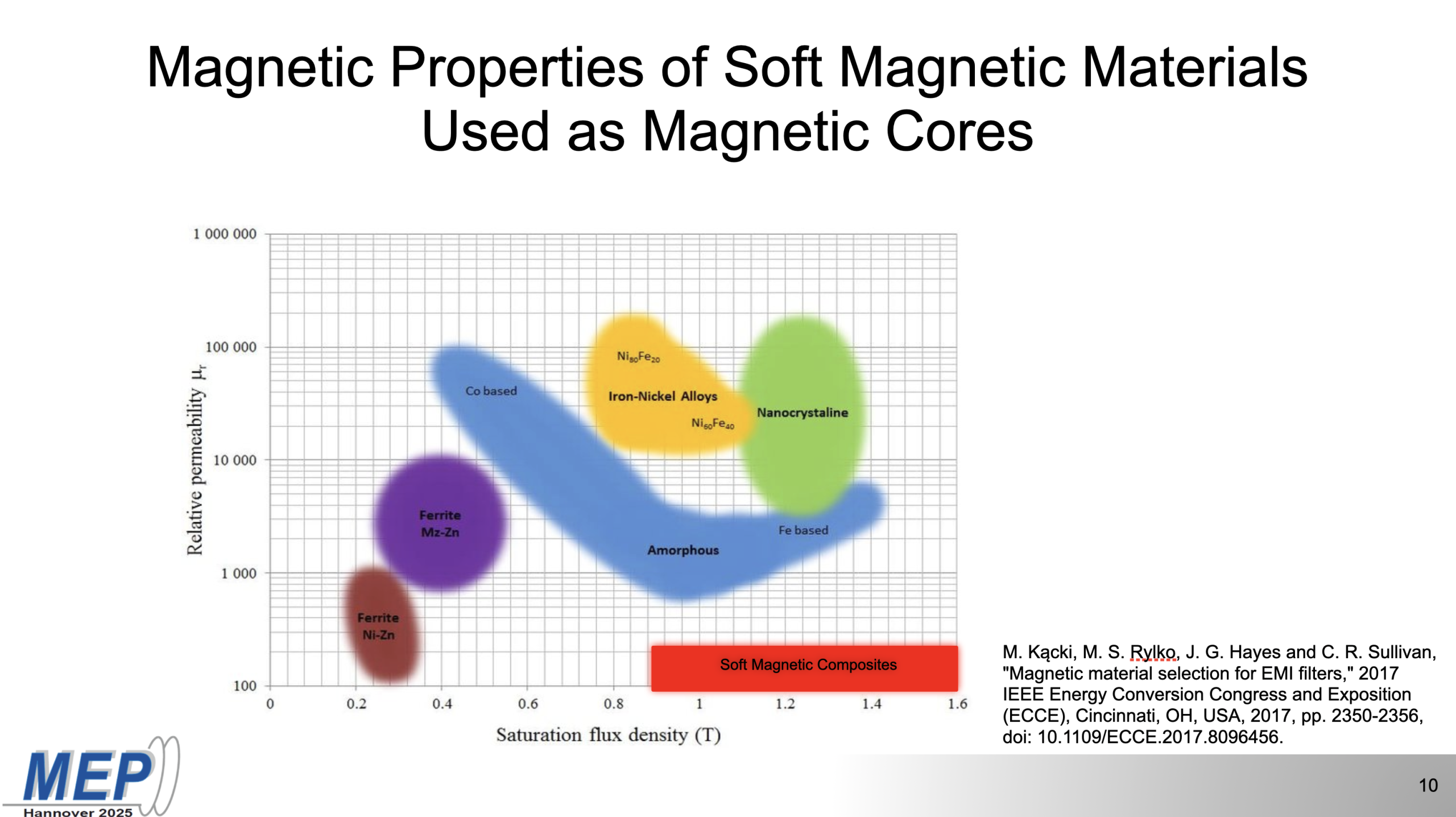

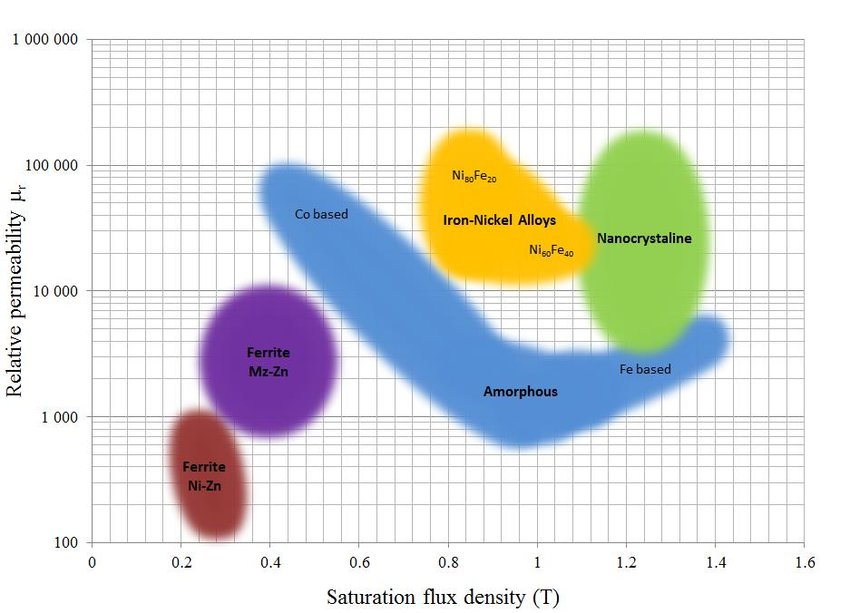

Magnetic Properties of Soft Magnetic Materials Used as Magnetic Cores

M. Kącki, M. S. Rylko, J. G. Hayes and C. R. Sullivan, "Magnetic material selection for EMI filters," 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 2017, pp. 2350-2356, doi: 10.1109/ECCE.2017.8096456.

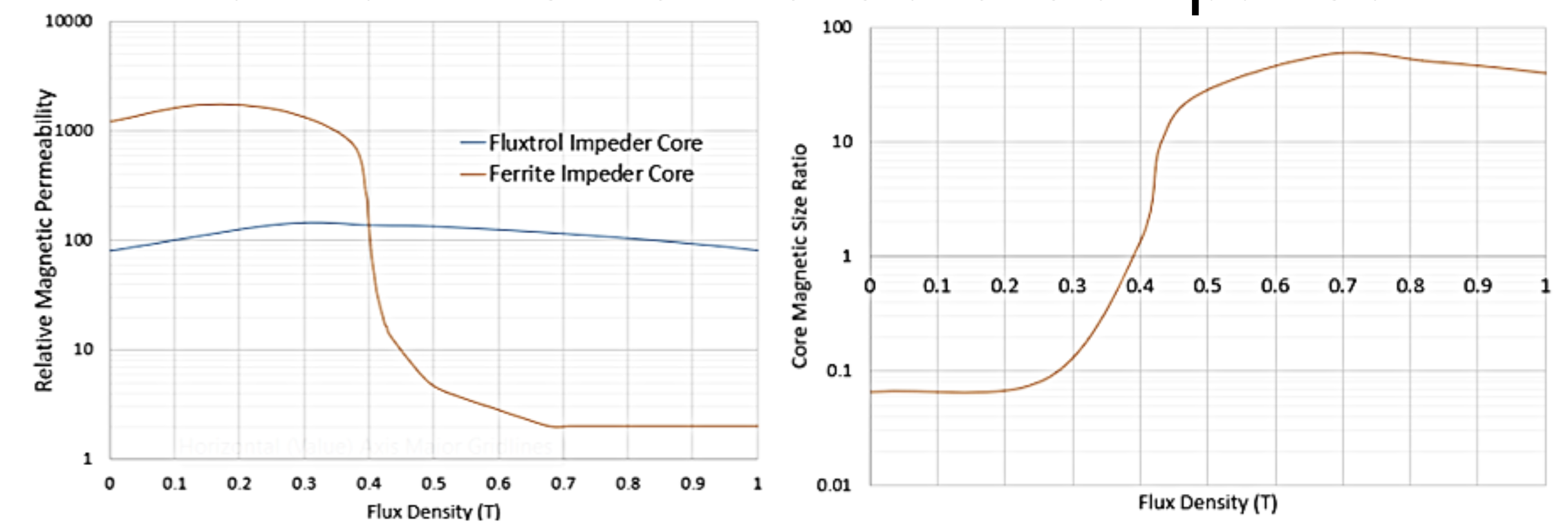

Fluxtrol A vs Ferrite Core Comparison

- Below their saturation flux density, typical ferrites used for impeders will outperform the Fluxtrol A material

- Above their saturation flux density, Fluxtrol A will outperform ferrites

- At the level of 0.7 Tesla and above, Ferrite will only be approximately 2 X better than air, while Fluxtrol A remains approximately 100 X better

SMC vs Ferrite Impeders

|

Advantages of SMC Higher Saturation Flux Density |

Disadvantages of SMC Cost of impeder |

Opportunities for SMC Impeders

- Small diameter, heavy-walled steel tubes

- Small tube applications where welder is the bottleneck and impeder is in saturation

- Applications where impeders frequently fail due to mechanical impact with line

- Applications with metallic components inside of the impeder

- Applications with very short impeder life

Barriers to Adoption

- Tests on a tube mill are very expensive

- 50 to 300 m/min line speeds typical

- Validation of new process can be very expensive

- Ferrites are proven technology and the current industry standard for decades

- SMC cores are 10 – 50 times more expensive to purchase on an individual unit basis

- Annual Costs of Impeders Only are often similar, production savings tend to be much higher

- SMC losses are higher, so good cooling is required

- Need to be mindful of water circuit design

Broader Impact

- Various case studies have shown 20-50% energy savings in small tube welding lines to produce at the same rates

- Given widespread adoption of more energy efficient SMC impeder cores, the opportunity in carbon reduction is on the order of tens of megatons of CO2 per year without initial capital investment required

- Additionally, the potential for longer lasting impeders and fewer changeovers increase line uptime and reduce scrap

Conclusions

-

- Many small tube welding installations are limited by the impeder

- SMC’s have the potential to greatly improve the performance of these installations

- 20 – 50% energy savings/carbon reduction

- Increased impeder and coil lifetime

- Production rate improvements

- Savings are €100’s of thousands annually per line

-

- SMC’s have higher magnetic losses, so it important to appropriately design the impeder core and cooling circuit